Technology

Constantly renewed cutting-edge technology

Plastecca has constantly renewed and highly automated cutting-edge technology.

Our machinery currently covers the range from 35 t to 250 t, with hydraulic and electric injectors. All machines are equipped with robots to automate production, minimising handling. We also have all the necessary peripheral equipment for optimum quality (temperature regulators, mould thermoregulators, milling machines beside the injector, humidification chambers, oven to stabilise parts).

Our structure means we can work with the most technical materials on the market. Our plant is equipped with a central dehumidifying unit with independent temperature control containers and a fully automated vacuum transport system.

At Plastecca we guarantee a highly stable continuous process.

Materials

Thermoplastics high-tech

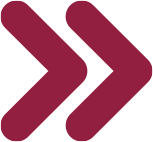

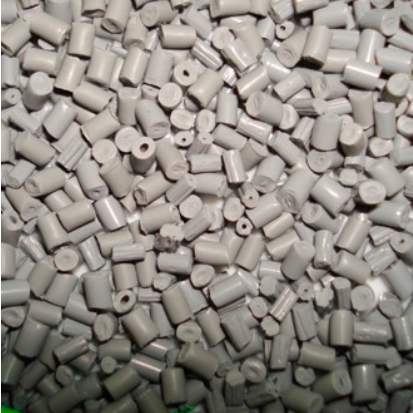

These provide the solution to industrial requirements. We work with high-performance materials, often with additives such as glass fibre, carbon, aramid, metals, minerals, microspheres and lubricants.

Engineering plastics for industrial applications with specific mechanical or thermal requirements, which may or may not also have additives, to achieve the desired performance.

The so-called commodities used for the highest consumption production items with better price requirements but without so many technical needs.

Future commitment

We also work with recycled materials from reliable, controlled sources, repetitive properties and sustainable, traceable suppliers.

We have a constantly developing wide range of BIOcompatible, BIOdecomposable, BIObased materials with ever-improving properties based on more sustainable organic materials. These are likely to be the future of some plastics that are currently massively used.

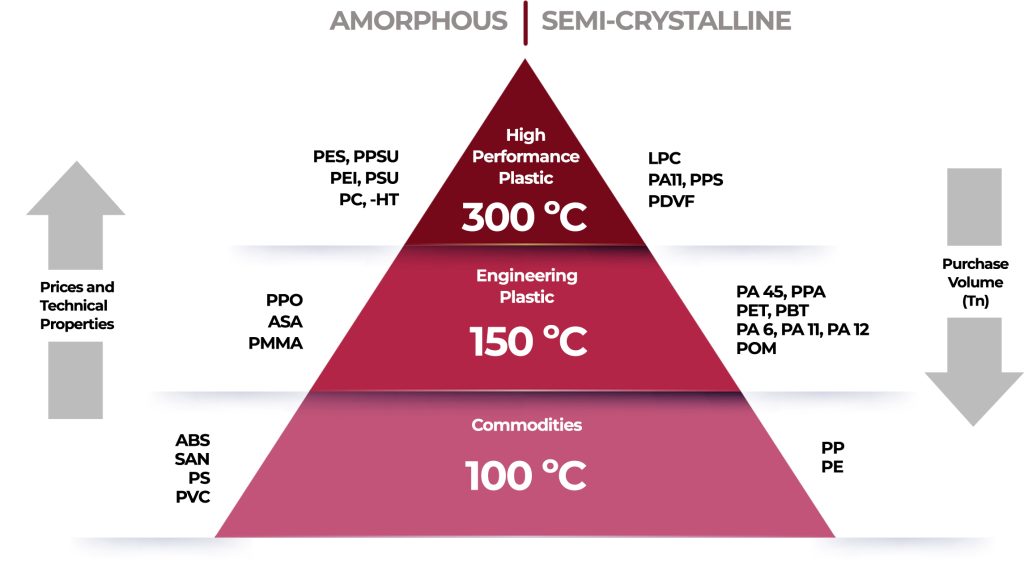

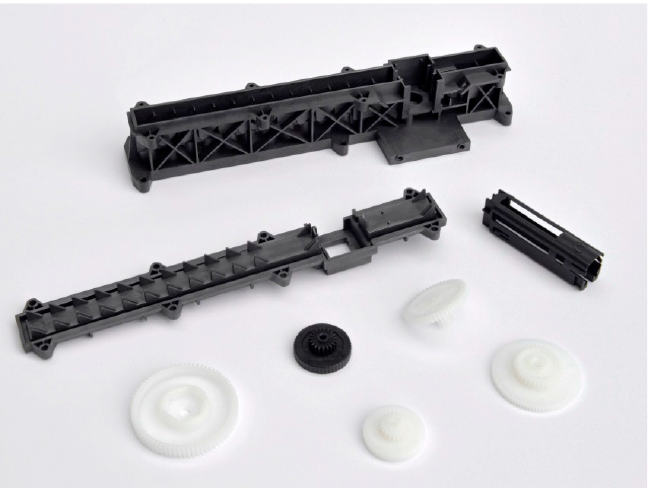

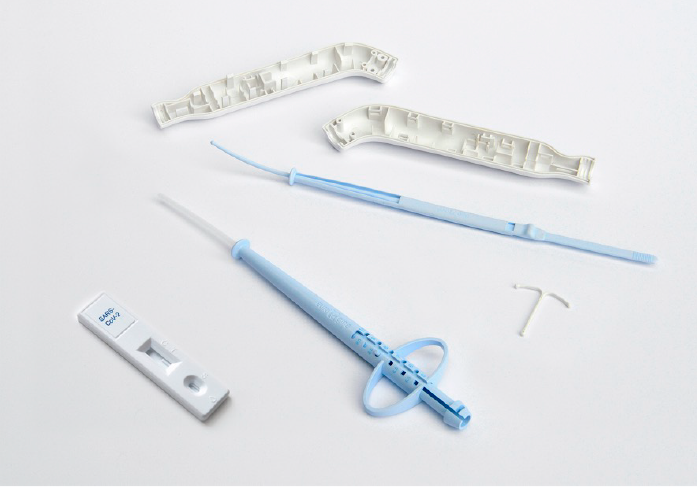

Examples

Do you want our advice on material options?